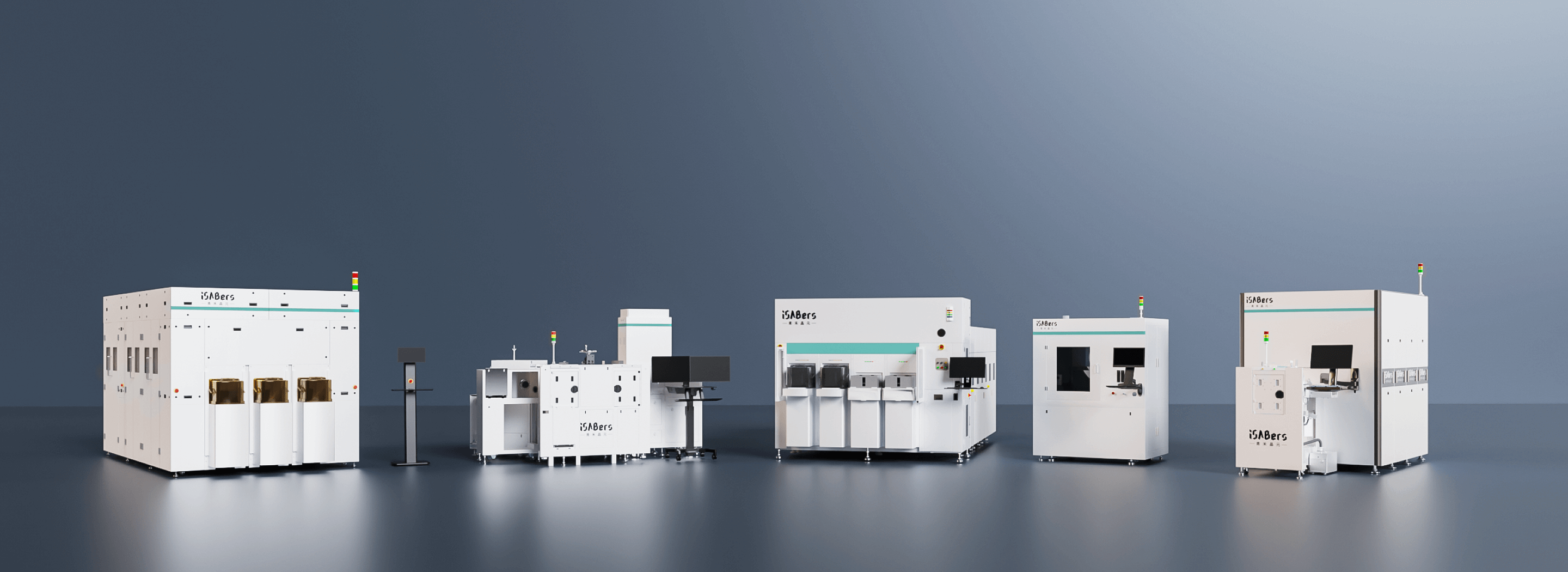

Bonding Equipment

- Wafer Bonding Equipment

- UHV RT Bonding Equipment

- Hydrophilic/Hybrid Bonding Equipment

- TC Anodic Bonding Equipment

- Temporary Bonding & Debonding Equipment

- Chip Bonding Equipment

- C2W/CWW Hybrid Bonding Equipment

- C2C & C2W TCB Bonding Equipment

- Surface Treatment Equipment for the Semiconductor Industry

- Super-atoms Beam Surface Treatment Equipment

Wafer Bonding Equipment

-

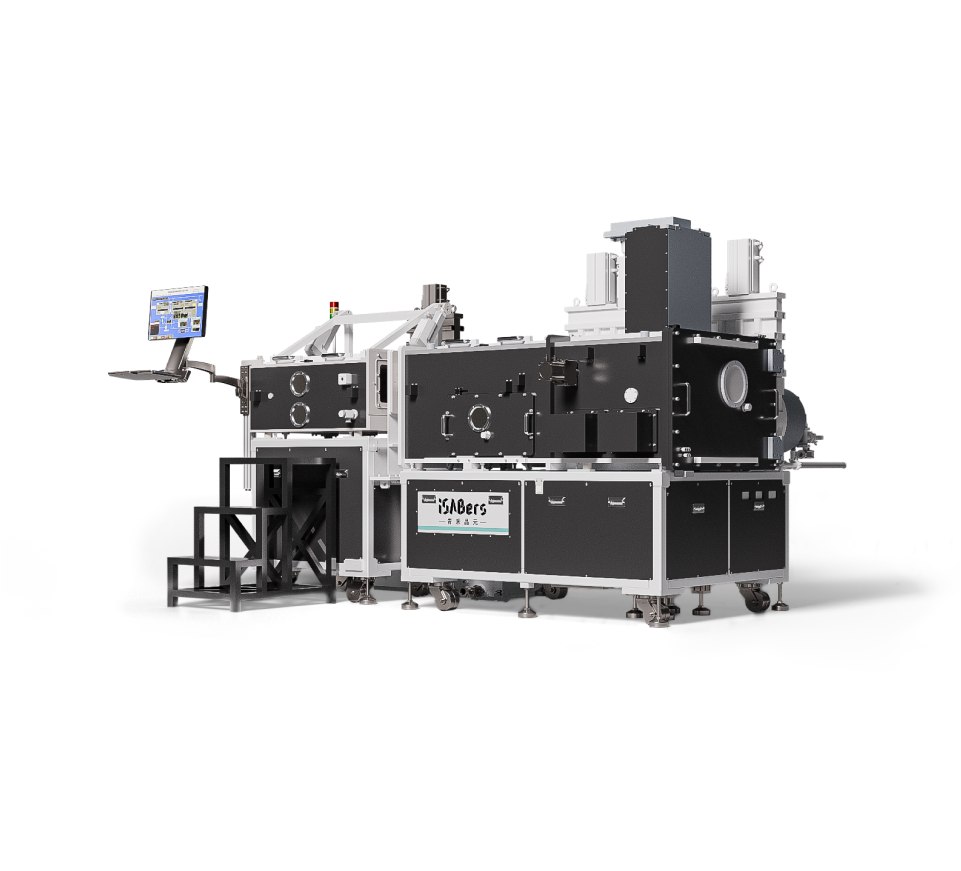

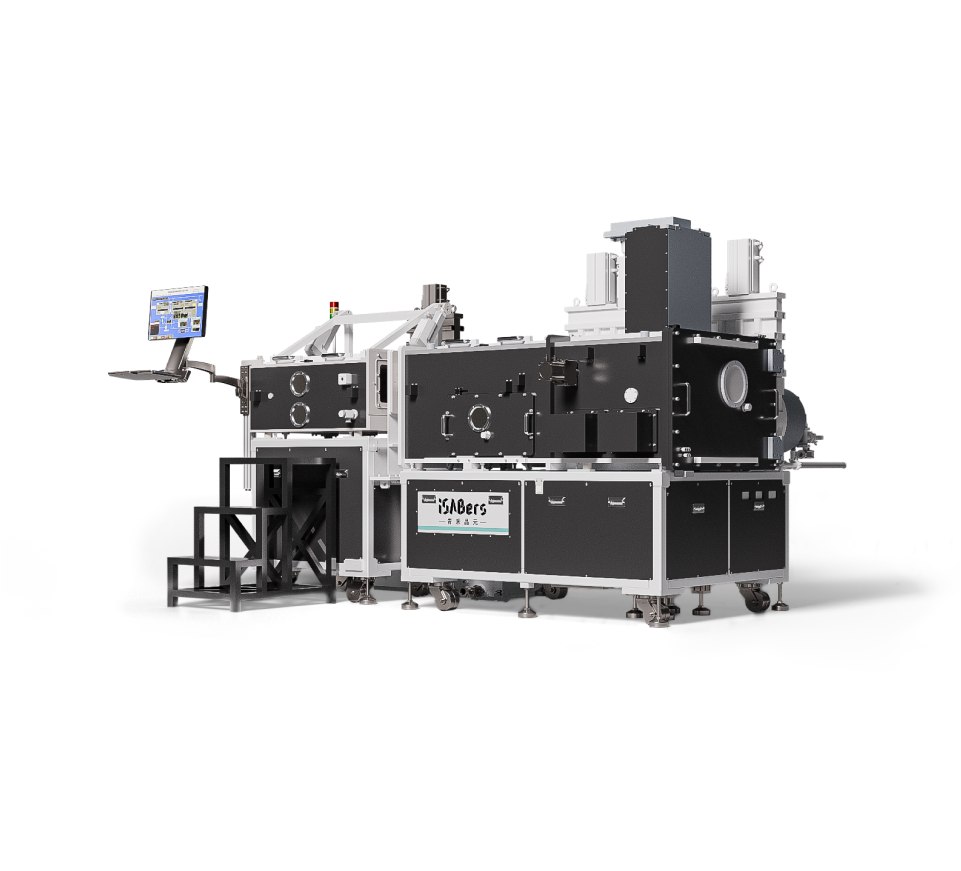

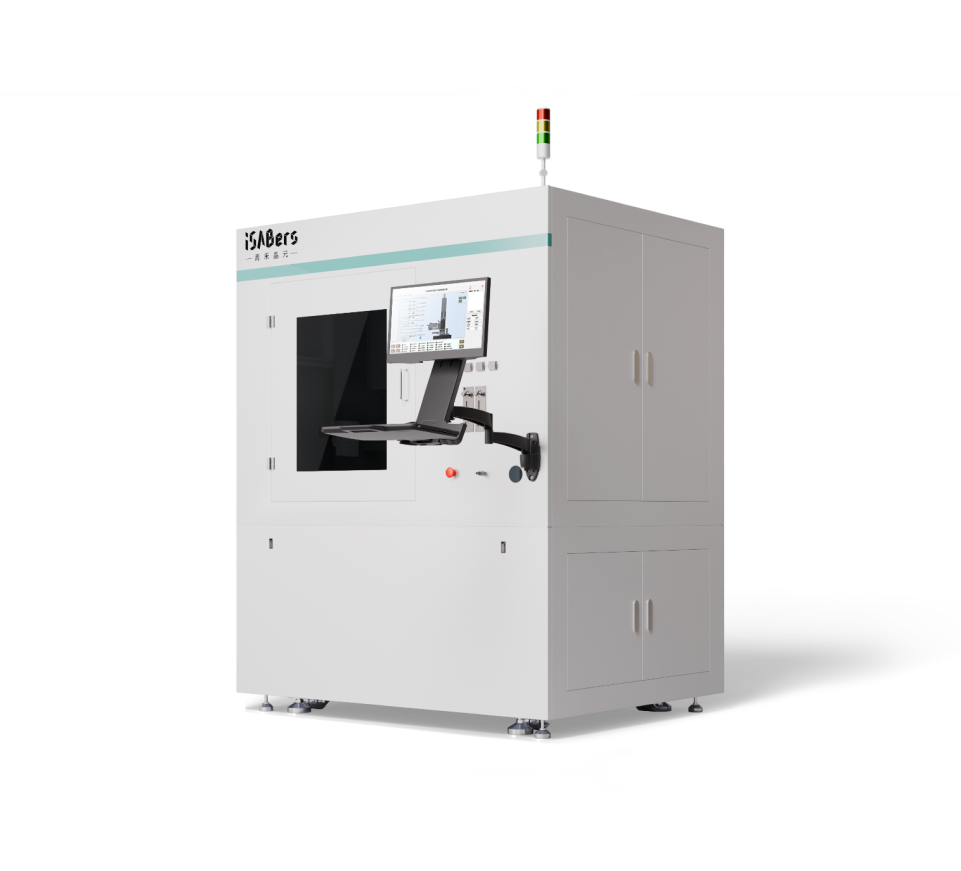

- SAB6100-Semi-automatic

- UHV RT Bonding Equipment

Learn MoreThe SAB6100 is an R&D-grade bonding system designed for semiconductor and heterogeneous material integration.Utilizing room-temperature UHV bonding technology, it enables atomic-level surface activation and direct covalent bonding without heating. The system accommodates full-size and custom-shaped wafers, supports optional dedicated deposition chamber, and ensures process stability and repeatability.

-

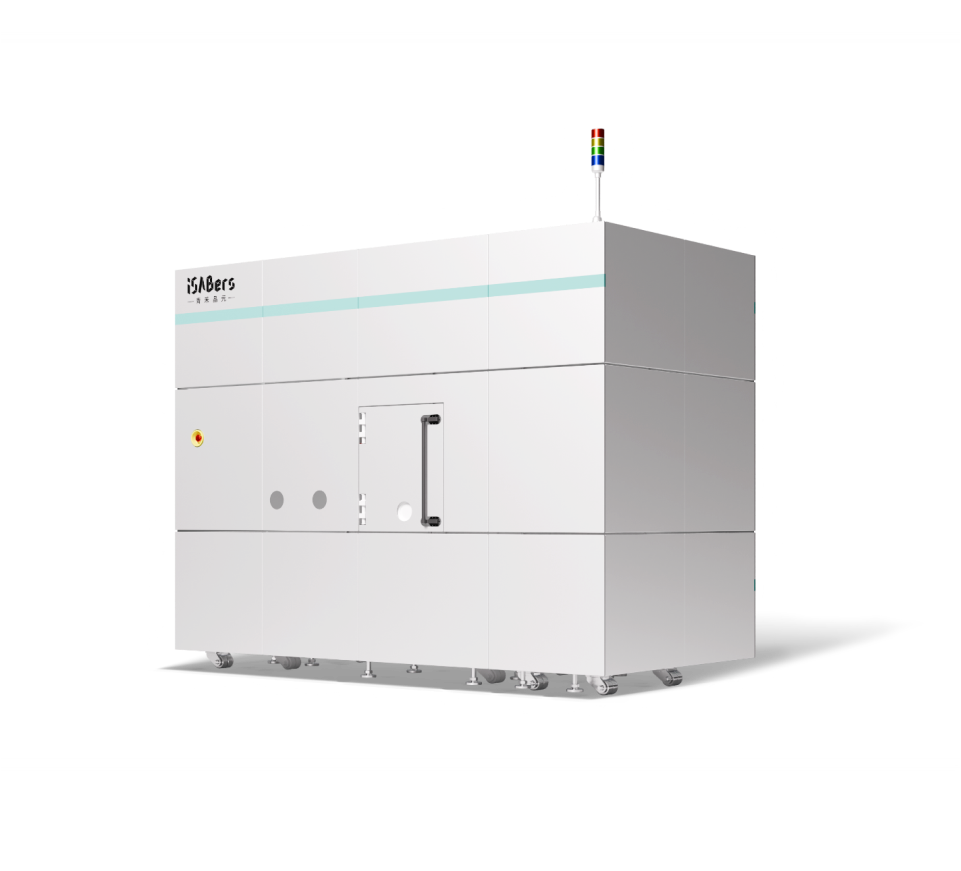

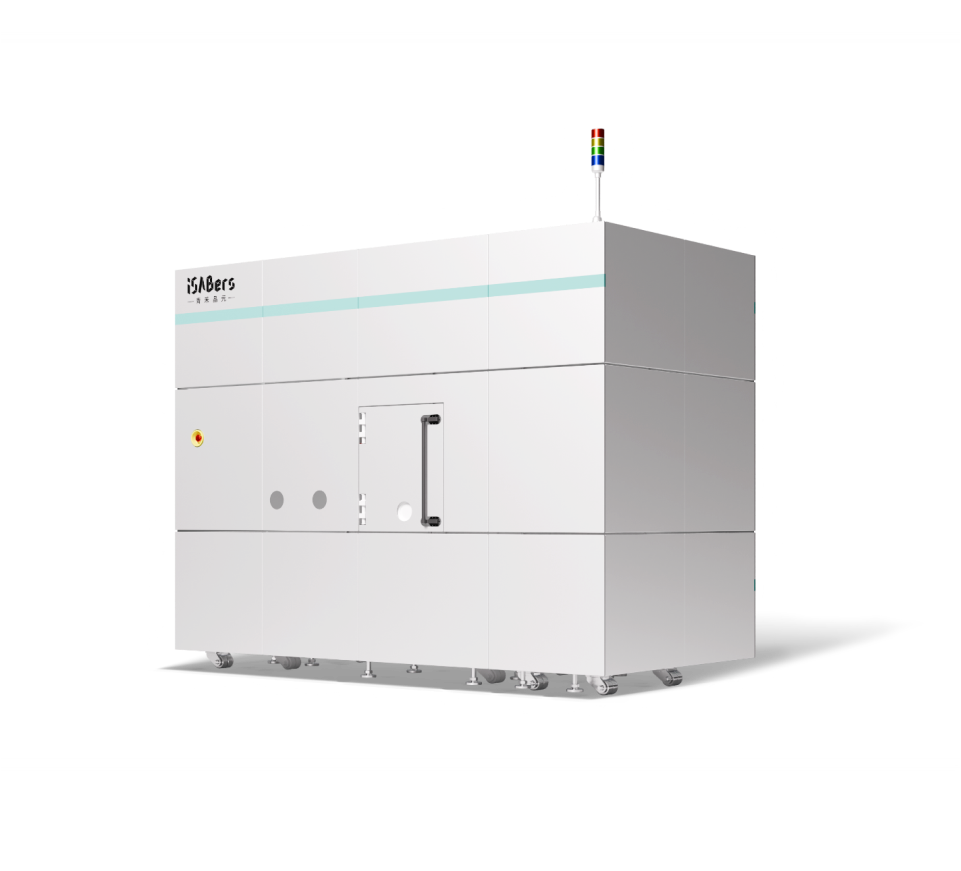

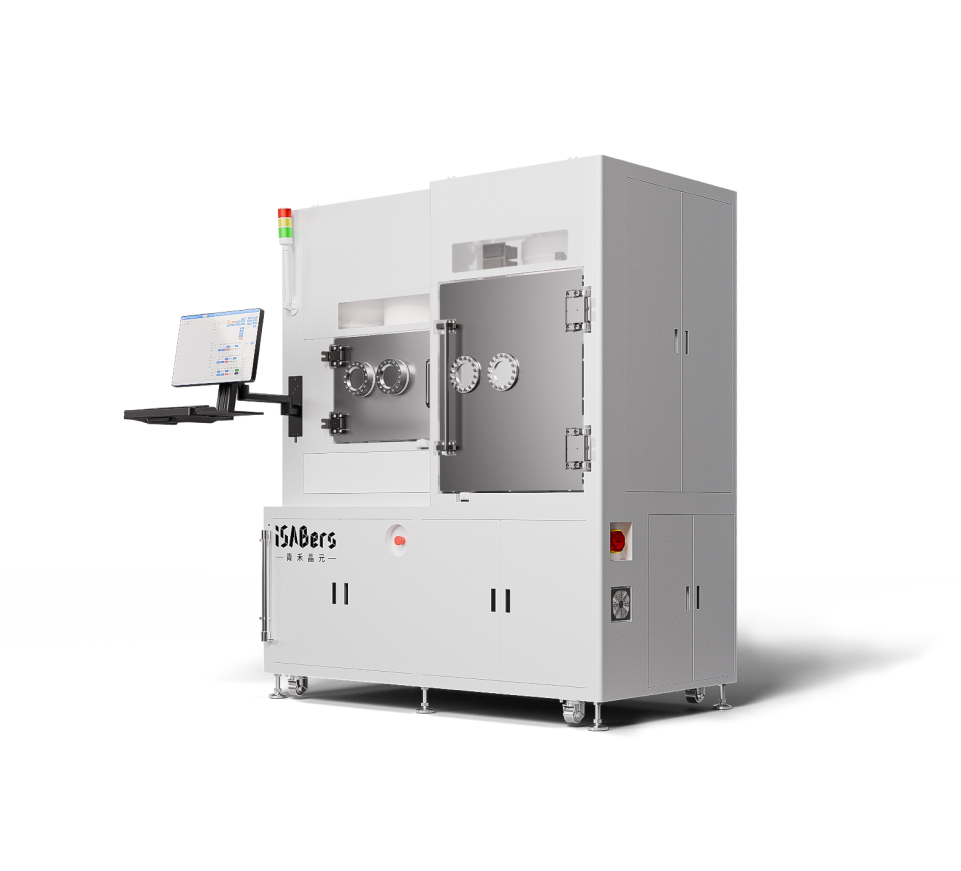

- SAB6110-Fully automatic

- UHV RT Bonding Equipment

Learn MoreThe SAB6110 is a high-throughput bonding system designed for semiconductor and heterogeneous material integration. Utilizing room-temperature UHV bonding technology, it enables atomic-level surface activation and direct covalent bonding without heating. It supports full-size compatibility and is equipped with automated wafer loading, independent deposition chamber, and high-precision alignment system, delivering stable processes and high-throughput production.

-

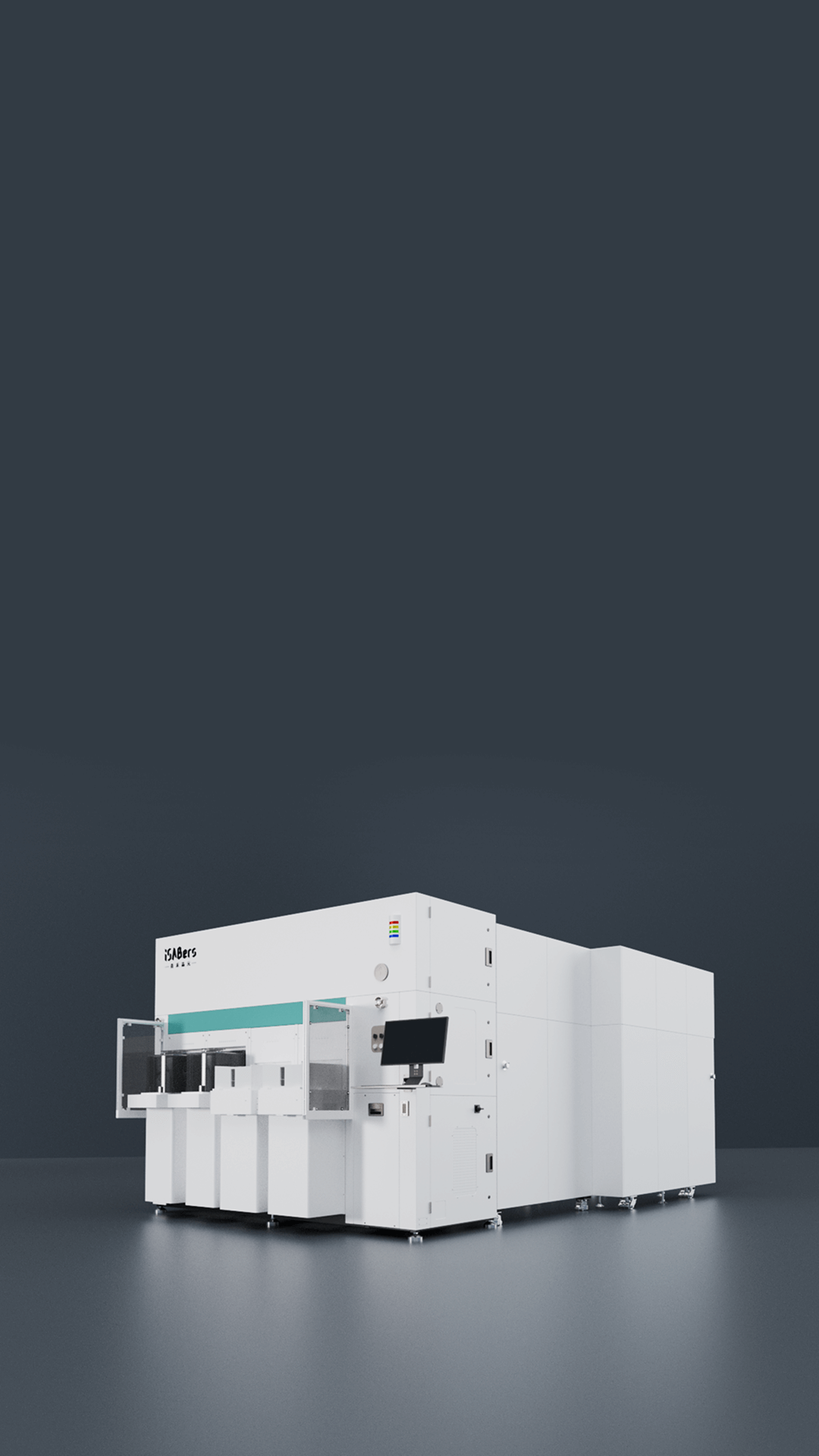

- SAB6110 CST-High-throughput Fully automatic

- UHV RT Bonding Equipment

Learn MoreThe SAB6110 CST is a high-throughput production system for semiconductor and heterogeneous material bonding, featuring a multi-chamber cluster design. It integrates activation, baking, sputtering (ion beam/magnetron), alignment, and bonding functions. Each chamber has independent dry and molecular pumps for rapid vacuum pumping. The activation module efficiently removes surface oxides, while the baking module rapidly eliminates moisture. It supports edge/mark alignment, cassette automated loading, and meets high-throughput production demands.

-

- SAB6210-Fully automatic

- Hydrophilic Bonding Equipment

Learn MoreThe SAB6210 is a hydrophilic fusion bonding system that utilizes plasma treatment and spin-rinse drying to enrich wafer surfaces with -OH groups, enabling alignment and bonding at room temperature in either atmosphere or vacuum.

-

- SAB6210 HB-Fully automatic

- Hybrid Bonding Equipment

Learn MoreThe SAB6210HB is a hybrid bonding system designed for wafers with patterned dishing Cu pads and dielectric materials (e.g., SiO₂ or SiCN). It enriches -OH groups on dielectric surfaces via plasma treatment and water rinse/spin-drying, enabling high-precision alignment (via MARK) and bonding in ambient atmosphere.

-

- SAB6300-Semi-automatic

- TC Anodic Bonding Equipment

Learn MoreThe SAB6300 is a versatile, semi-automatic bonding system for R&D and small-batch production. It supports thermocompression bonding and anodic bonding, enabling diffusion bonding of metals (Au, Cu, Al, etc.), eutectic materials (Au-Sn, Al-Ge, etc.), or adhesives through precise temperature and pressure control. It also achieves glass-to-silicon bonding via electrostatic field application combined with heating and pressurization.

-

- SAB6310-Fully automatic

- TC Anodic Bonding Equipment

Learn MoreThe SAB6310 is a fully automated bonding system compatible with thermocompression and anodic bonding. It integrates plasma activation, cleaning, alignment, and bonding modules for high-quality, high-throughput production.

-

- SAB6410TB-Fully automatic

- Temporary Bonding Equipment

Learn MoreThe SAB6410TB is a fully automated temporary bonding system integrating spin coating, baking, alignment, and bonding functions. It bonds two wafers with adhesives to enable backside processing of device wafers.

-

- SAB6410DB-Fully automatic

- Debonding Equipment

Learn MoreThe SAB6410DB is a fully automated debonding system that performs debonding through mechanical, thermal-sliding, or laser-scanning methods, ensuring zero damage to wafers, temporary carriers, and patterned layers. Post-debonding cleaning (chemical or plasma) guarantees residue-free surfaces with no adhesive remnants, watermarks, carbon ash, or other contaminants.

Chip Bonding Equipment

-

- SAB8210CW-Fully automatic

- C2W Hybrid Bonding Equipment

Learn MoreThe SAB8210CW is a fully automated C2W hybrid bonding system. It supports C2W hybrid bonding with patterned chips to achieve high-density Cu-Cu interconnects, as well as C2W hydrophilic bonding with unpatterned bare dies to form reconstituted wafers for subsequent die patterning.

-

- SAB8210CWW-Fully automatic

- C2W/W2W Hybrid Bonding Equipment

Learn MoreThe SAB8210CWW is a fully automated hybrid bonding system integrating C2W (Chip-to-Wafer) and W2W (Wafer-to-Wafer) dual modes. It supports 8/12-inch wafers and handles ultra-thin chips (down to 35μm) of various sizes. The system enables parallel development and validation of C2W and W2W processes, significantly shortening the R&D-to-production transition timeline.

-

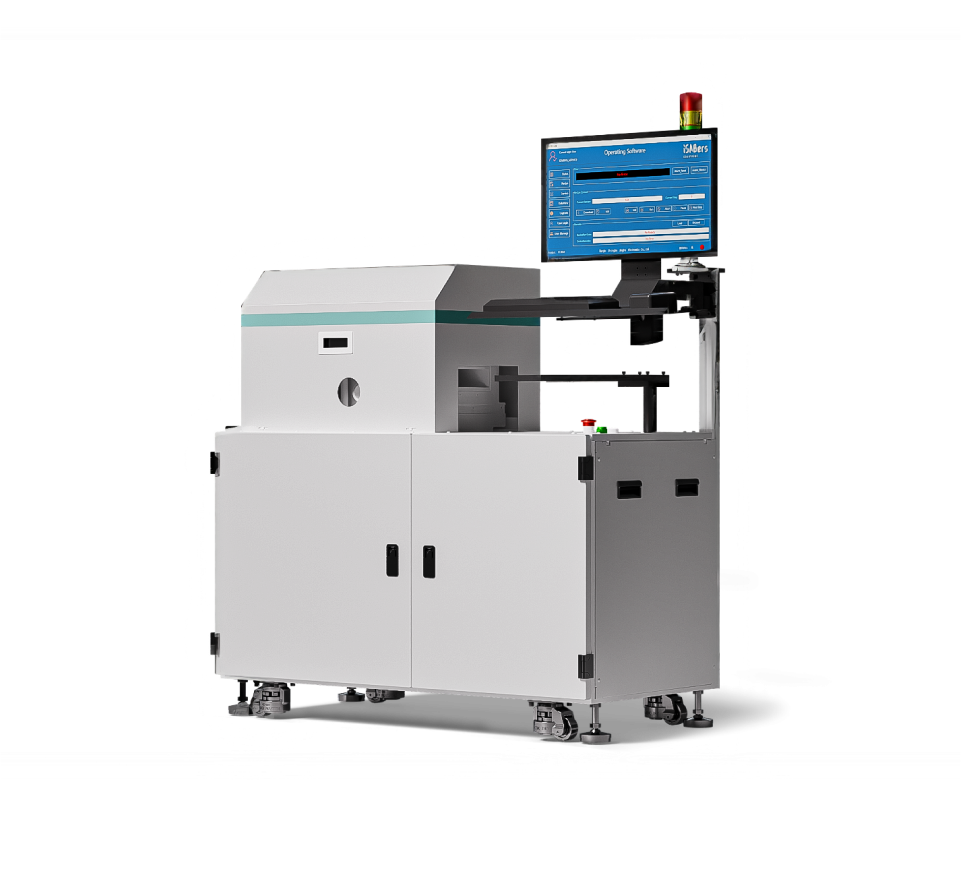

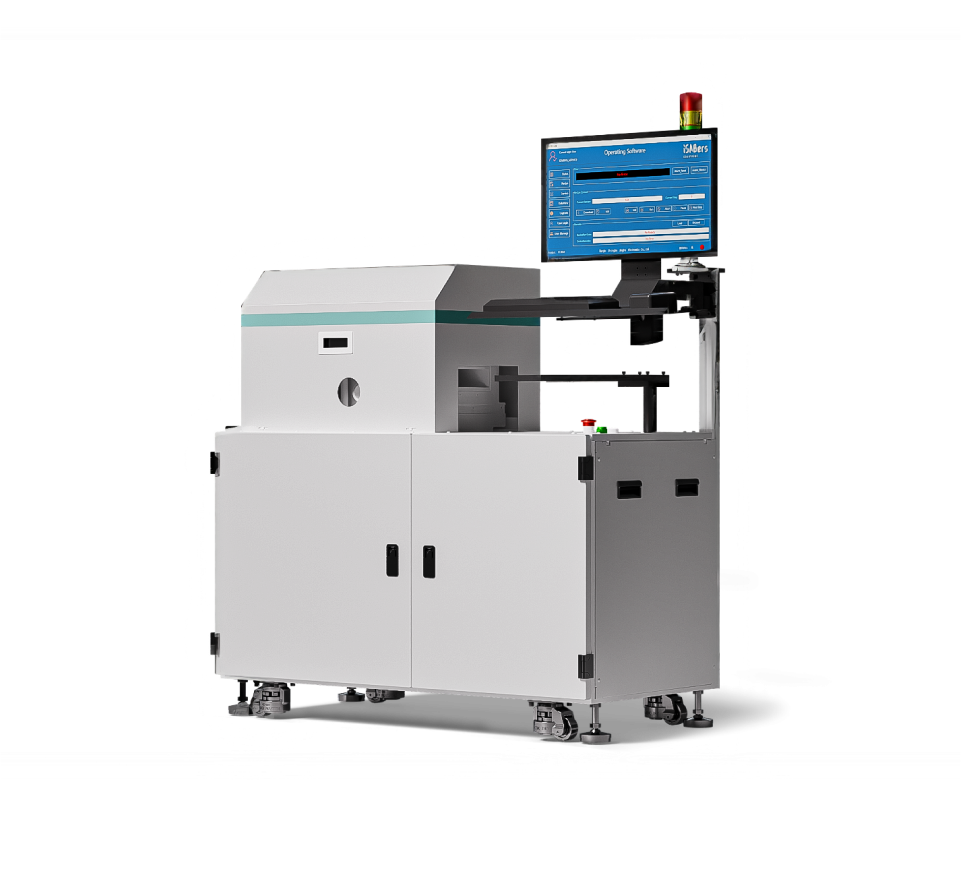

- SAB8300-Semi-automatic

- C2C TCB Equipment

Learn MoreThe SAB8300C2C is a semi-automatic flip-chip bonding system designed for R&D, sample validation, and small-batch production. It enables high-precision alignment and reliable interconnects between micro-bumps and pads in an inert gas or hydrogen radical environment.

-

- SAB8310CW-Fully automatic

- C2W TCB Equipment

Learn MoreThe SAB8310CW is a fully automated C2W flip-chip (alignment&thermocompression) bonding system for high-volume production. It supports automatic wafer/chip loading/unloading, and independent hydrogen radical and plasma activation chambers for high-quality fluxless TCB bonding.

Surface Treatment Equipment for the Semiconductor Industry

-

- SAB9500-Semi-automatic

- Super-atomic Beam Polishing Equipment

Learn MoreThe SAB9500 is a semi-automatic ultra-atomic beam polisher for ultra-precision surface polishing of 2-12 inch wafers or irregularly shaped samples. Compatible materials include Si, SiC, InP, GaAs, GaN, diamond, LN, LT, optical crystals, and more.

-

- SAB9510-Fully automatic

- Super-atomic Beam TRIM Equipment

Learn MoreThe SAB9510 is a fully automated Super-atomic Beam surface TRIM system with cassette-based loading/unloading, siutable for high-volume production for semiconductor film TRIM.