Features

-

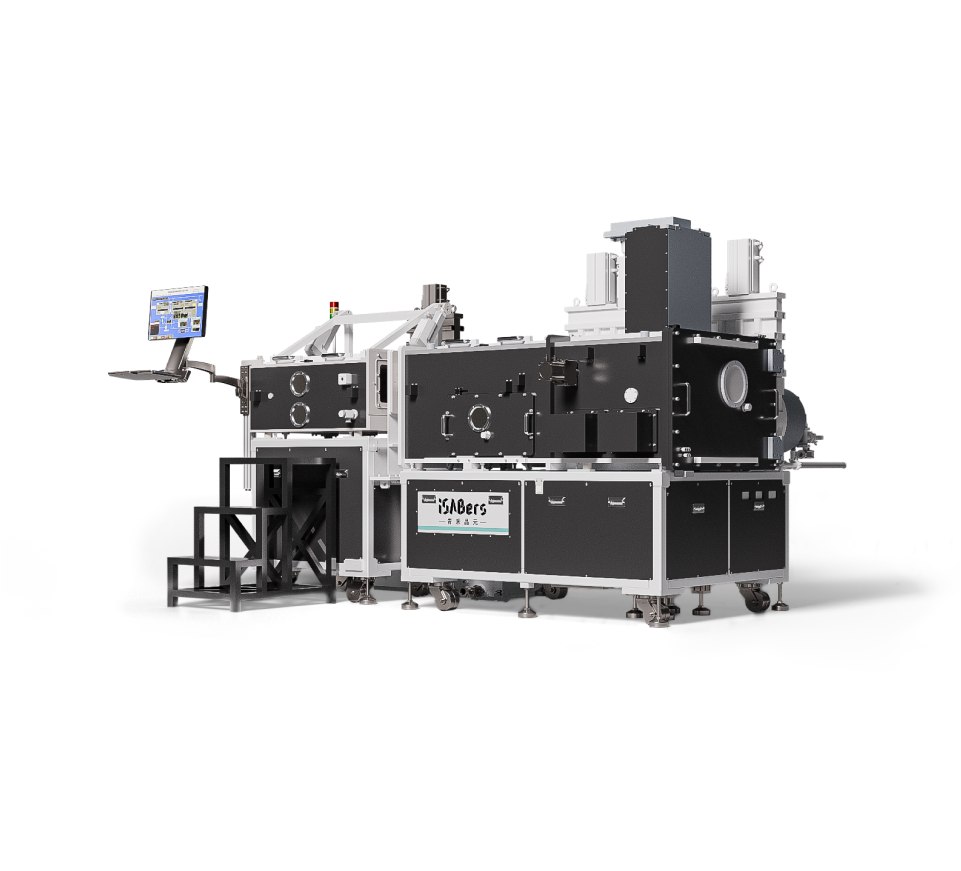

- Full-size High-volume Production

- Supports 6-12 inch wafers with integrated edge-finding/plasma activation/cleaning/bonding modules, achieving 14 WPH throughput.

-

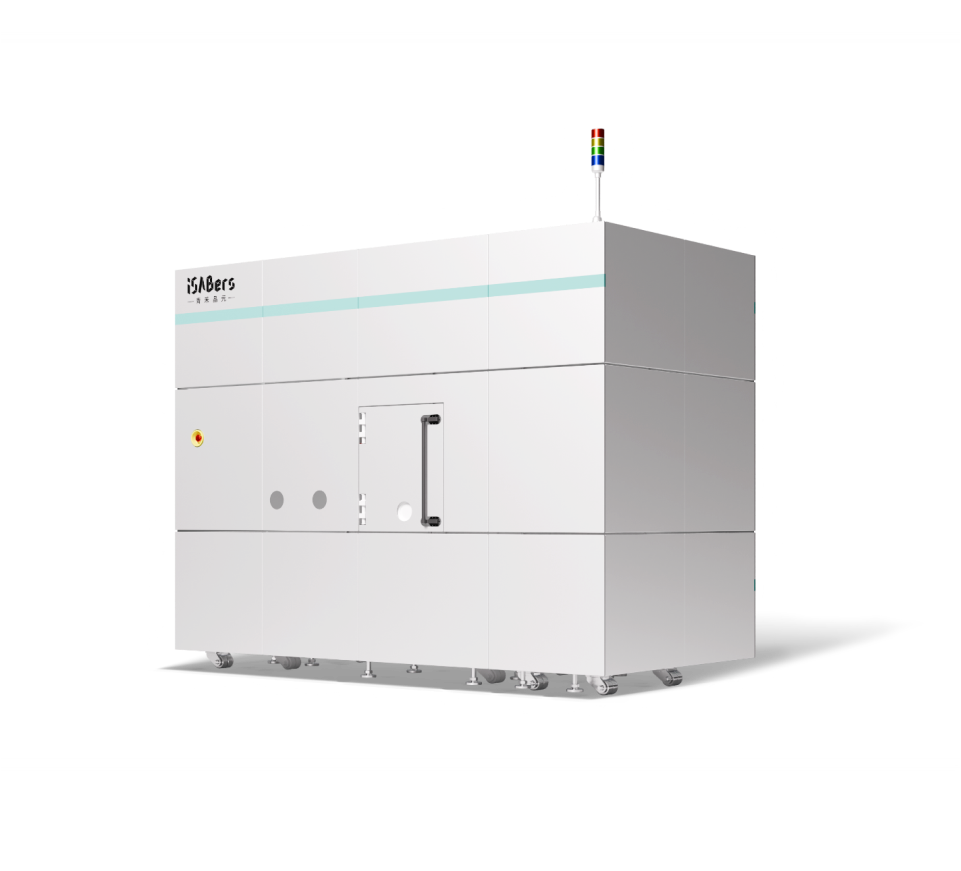

- Optional Cavity Fusion Bonding

- After high-precision alignment, wafers are fixed on chucks and transferred to a vacuum chamber for bonding, with bonding accuracy ≤±0.5 μm.

-

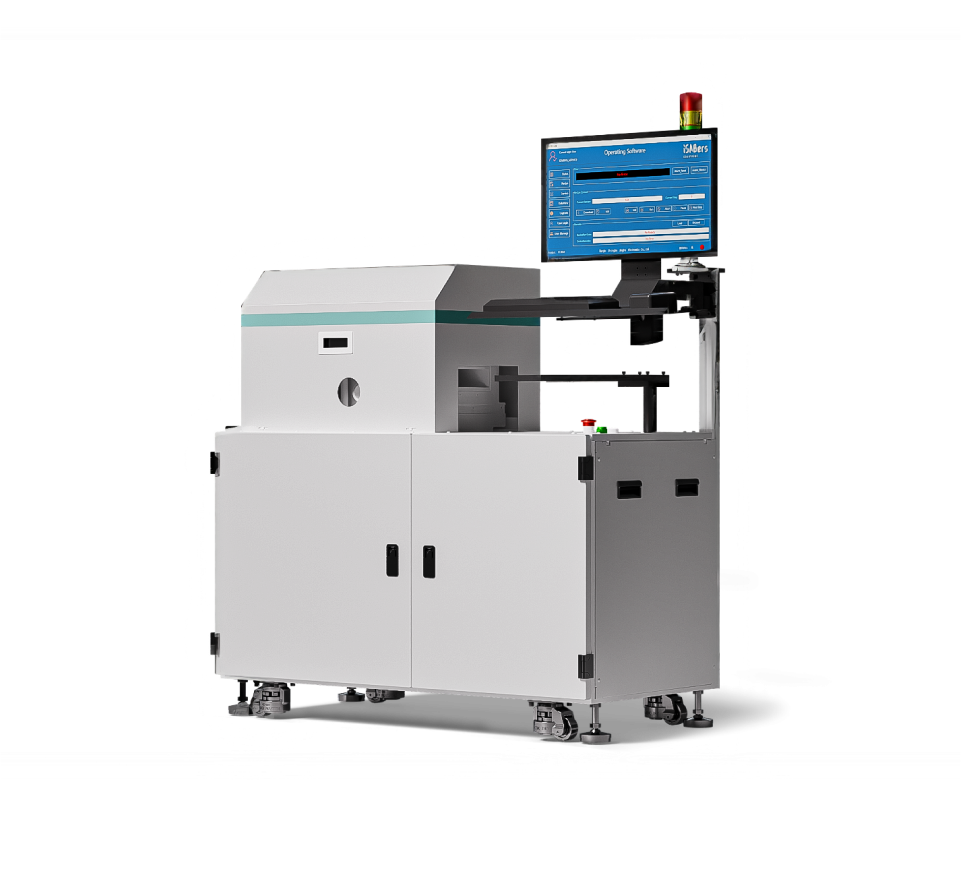

- Exceptional Bonding Yield

- Upgraded plasma activation, megasonic/two-fluid cleaning technologies, and bond wave propagation control eliminate bonding voids and enhance yield.

-

- Intelligent Defect Recognition

- Smart algorithms precisely identify bonding voids and other defects. Defective wafers can be debonded and reused.

Specifications

-

ltemsSpecification

-

Wafer size6,8,12 inch

-

Bondable materialsSOI、POI

-

Capacity≥14 pairs/h

-

Wafer loadCassette、SMIF、Foup Optional

-

Alignment accuracyMechanical alignment: ≤ ±50μm;Optical: 0.5μm(Cavity bonding)

-

Bond strength≥2.0J/m² (Si-SiO2, after annealing)

-

Multi-module integratedPre-align, plasma activation, clean, align, bond, detection,debonding

-

Chemical cleanOptional

-

Internal cleanlinessFFU control, ISO Class 1