Features

-

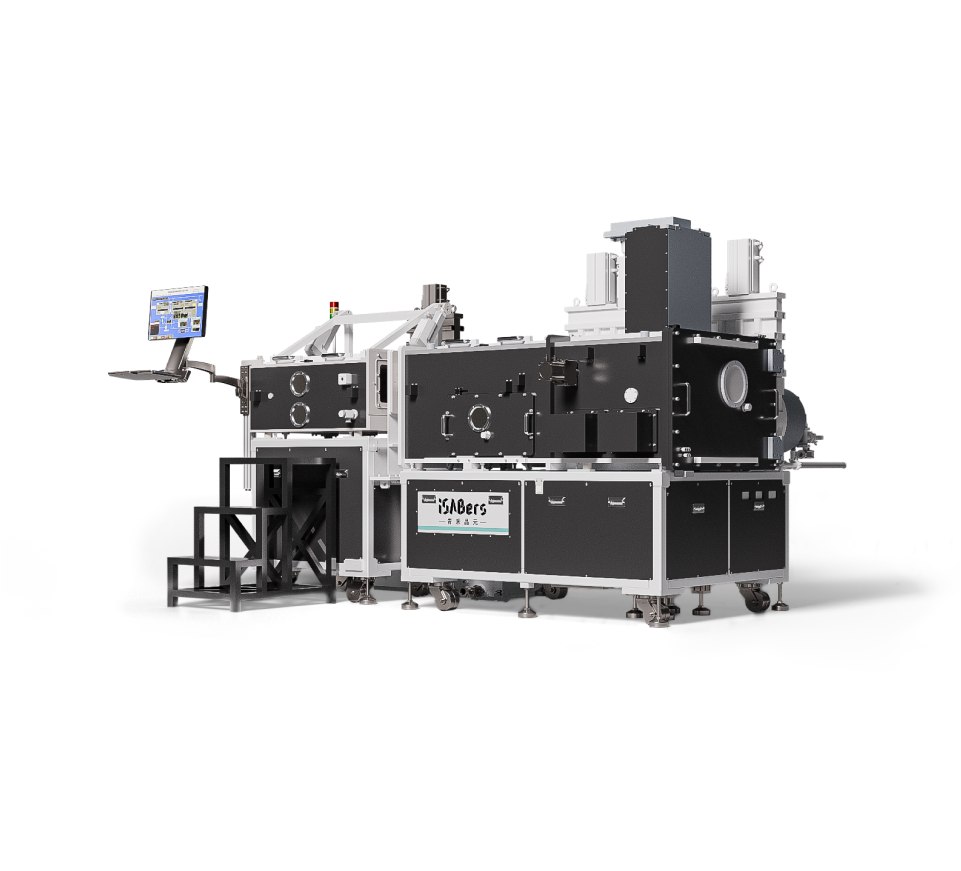

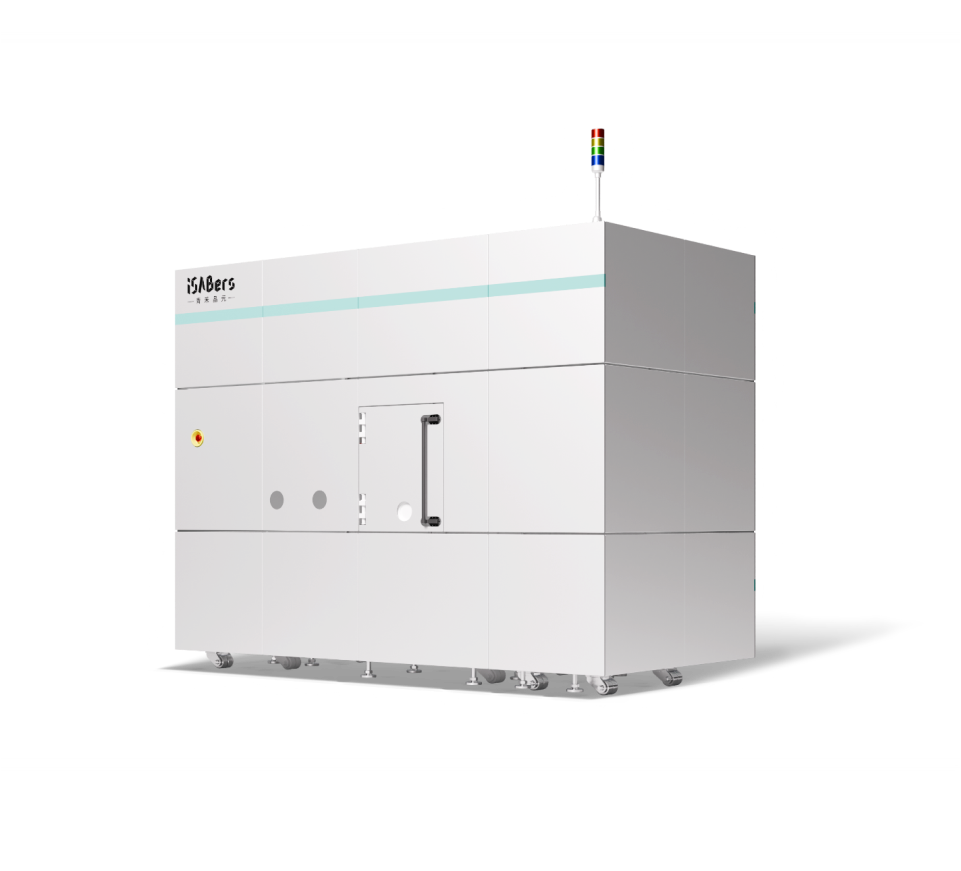

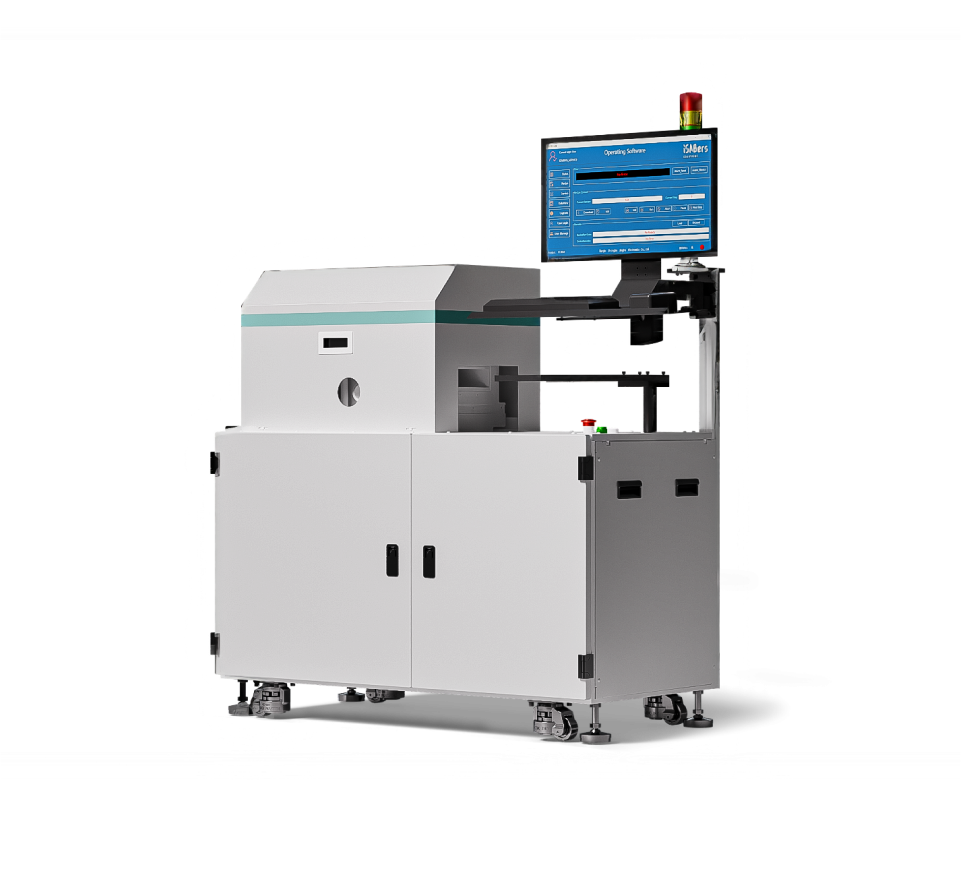

- Flexible Debonding Methods

- Supports single or combined use of mechanical, thermal-sliding, or laser debonding.

-

- Low-stress Thermal Slip Debonding

- Independent temperature control for upper/lower plates, coupled with stable thermal-sliding control, minimizes breakage rates.

-

- Zero Damage Laser Debonding

- UV nanosecond laser with real-time focusing and power compensation achieves near-zero thermal damage during debonding.

-

- Zero-residue Debonding

- Chemical and plasma dry cleaning ensure >99.9% adhesive removal.

Specifications

-

ltemsSpecification

-

Wafer size4,6,8,12inch

-

Wafer loadCassette,SMIF,Foup Optional

-

Debonding methodMechanical ,Thermal-sliding, laser debond

-

Thermal-sliding TemperatureMaximum Temperature 250°C, independent upper/lower plate control

-

Thermal-sliding Speed0.1mm/s~70mm/s

-

Laser Wavelength355nm

-

Laser Spot ProfileTop-hat

-

Laser Maximum Scanning area320mm*320mm

-

Cleaning Chemical Type≥2

-

Maximum Spin Speed for Chemical Cleaning3000rpm

-

Plasma CleaningOptional

-

Multi-module integratedDebonding, separation, chemical cleaning, plasma cleaning.