Features

-

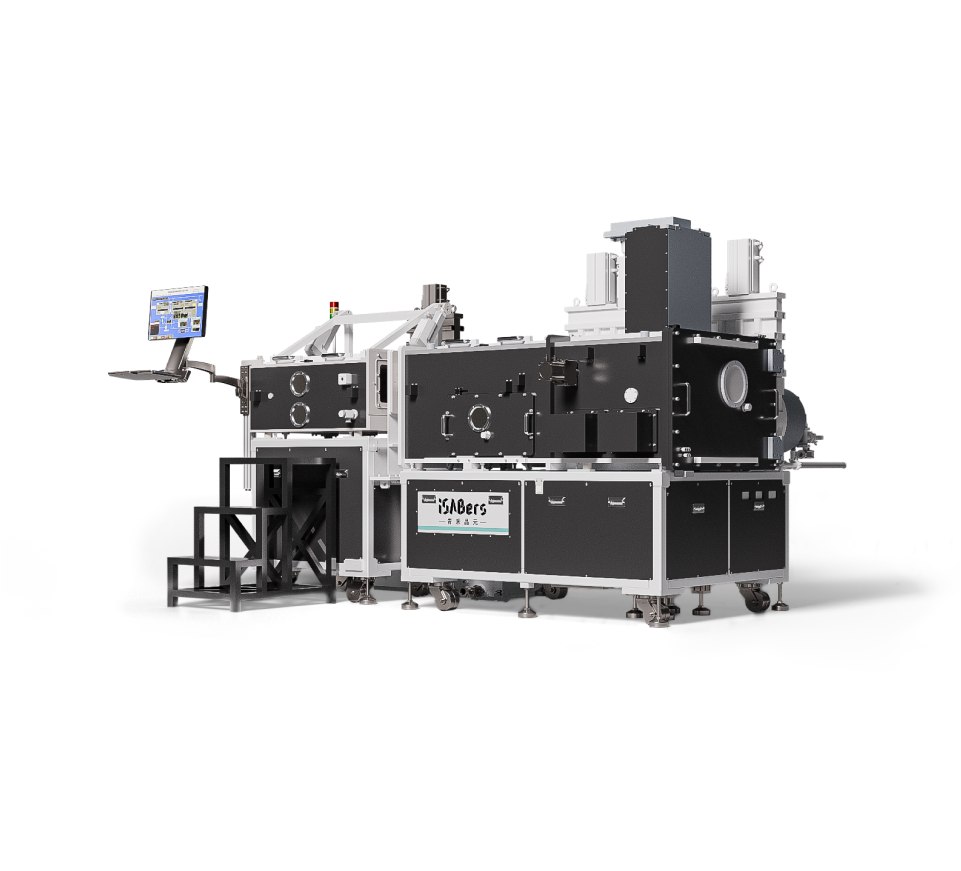

- Dual-Mode Process Integration

- A highly flexible modular design combines C2W and W2W hybrid bonding.

-

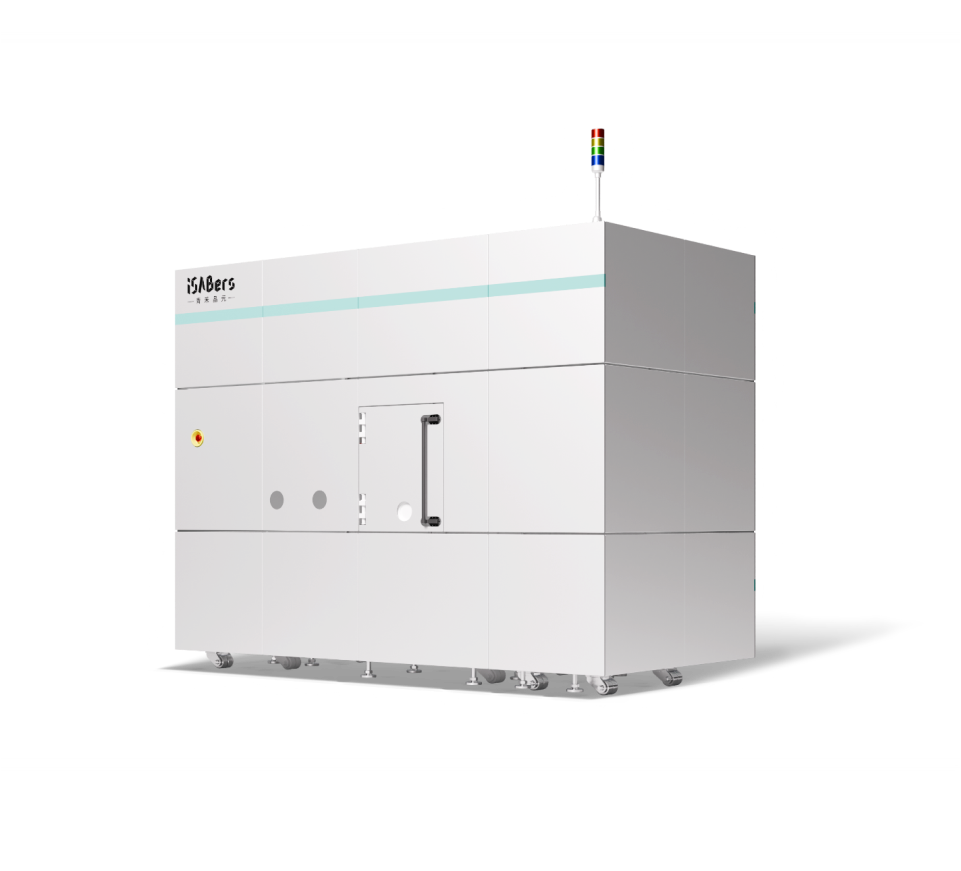

- 30% Reduction in Investment Cost

- Integrated architecture eliminates redundant modules compared to separately purchasing C2W and W2W systems.

-

- 60% Reduction in Footprint

- Compact design minimizes floor space compared to separately purchasing C2W and W2W systems.

-

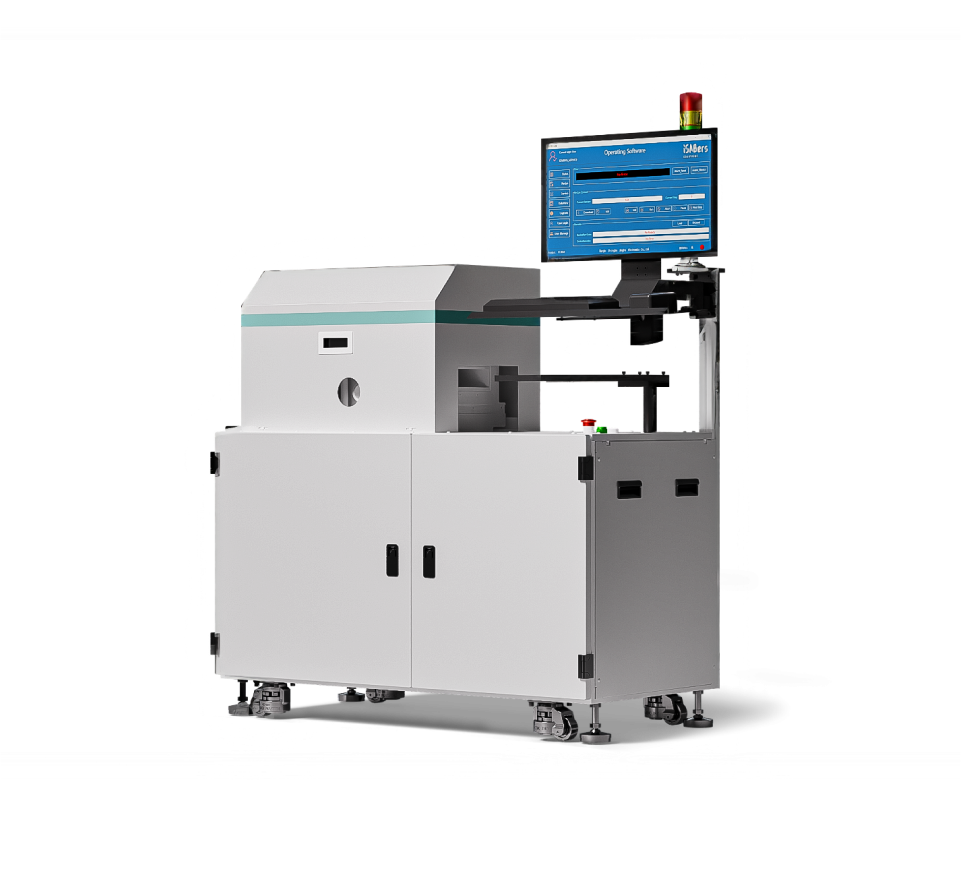

- Enhanced Module Utilization

- Plasma activation and cleaning modules can be used for W2W bonding during C2W bonding operations, eliminating idle time and maximizing efficiency.

Specifications

-

ltemsSpecification

-

Wafer size8,12 inch

-

Chip size5*8mm—50*50mm (Infrared transmissive alignment, tape frame loading)

0.5*0.5mm—50*50mm (Inter-chip coaxial alignment, tape frame loading) -

W2W Bonding accuracy≤±100nm

-

W2W Maximum bonding force300N

-

W2W Pressure control resolution1N

-

W2W CapacityWPH≥12

-

C2W Bonding accuracy≤±500nm@inter-chip coaxial alignment

≤±200nm@Infrared transmissive alignment -

C2W Maximum bonding force300N

-

C2W Pressure control accuracy±0.5N(0-50N)/±2N(50-300N)

-

C2W Capacity400~2000UPH(single bonding head)