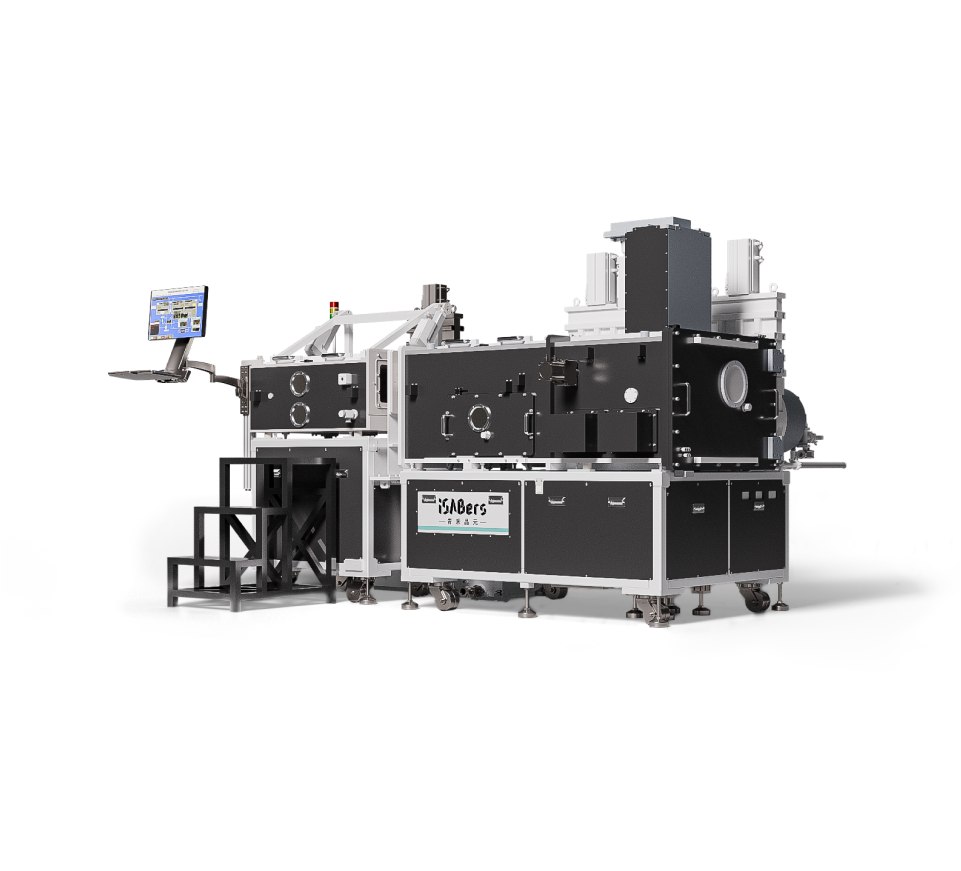

- SAB6110 CST-High-throughput Fully automatic

- UHV RT Bonding Equipment

The SAB6110 CST is a high-throughput production system for semiconductor and heterogeneous material bonding, featuring a multi-chamber cluster design. It integrates activation, baking, sputtering (ion beam/magnetron), alignment, and bonding functions. Each chamber has independent dry and molecular pumps for rapid vacuum pumping. The activation module efficiently removes surface oxides, while the baking module rapidly eliminates moisture. It supports edge/mark alignment, cassette automated loading, and meets high-throughput production demands.

-

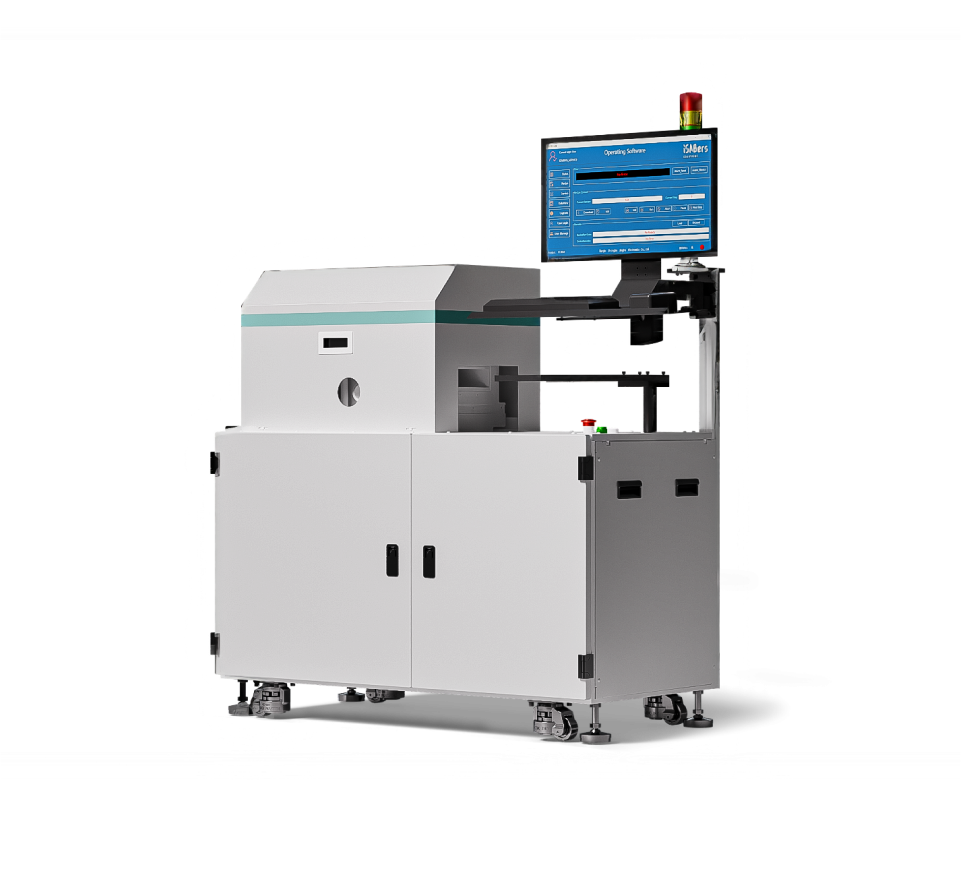

2-12inch

-

Compatible wafer size

-

±1%

-

Pressure control accuracy

-

≤±1μm

-

Bonding accuracy

-

WPH≥12

-

Throughput