Features

-

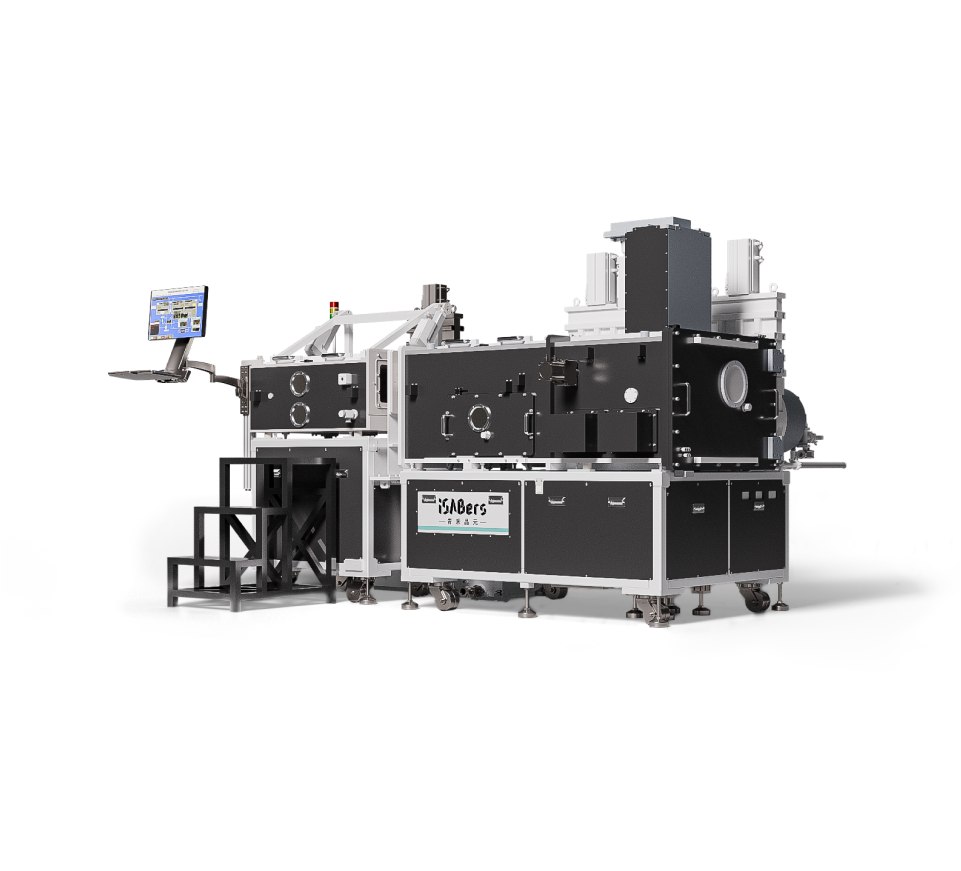

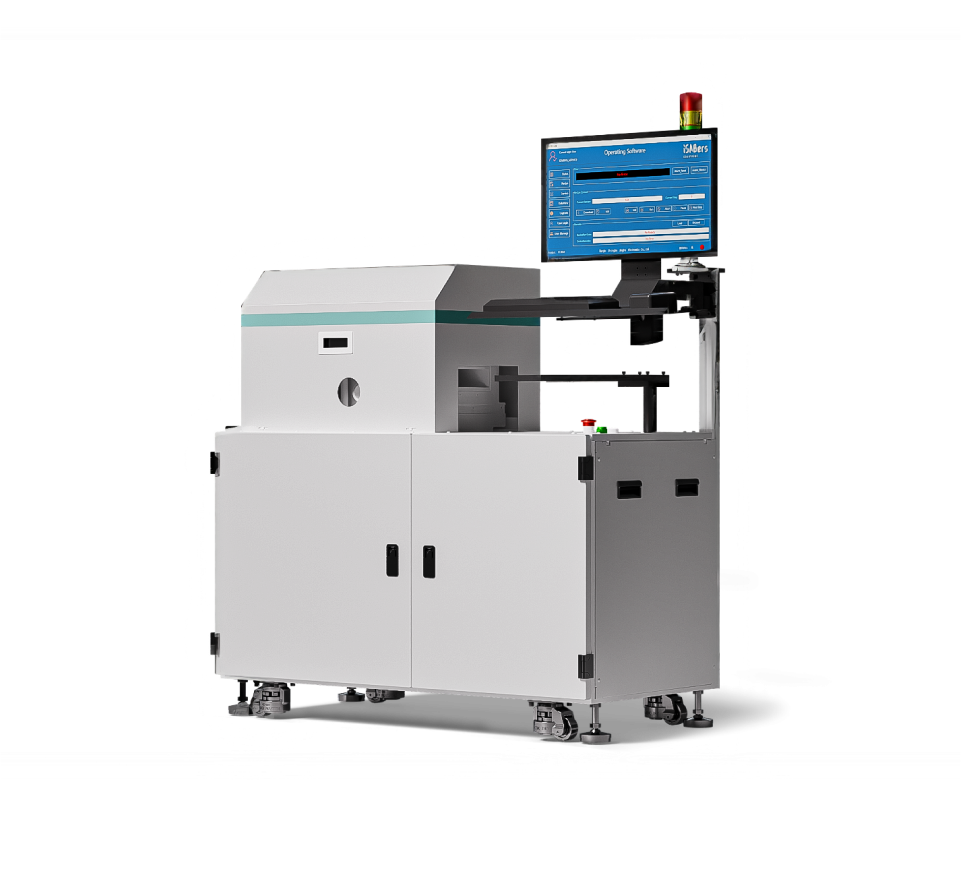

- Real-time Automated Leveling & Alignment

- Automated leveling between chips and wafers with real-time parallelism monitoring at bonding positions, achievs bonding accuracy up to ±500 nm.

-

- Dual Activation Modes

- Independent hydrogen radical and plasma activation chambers. Hydrogen radicals enable low-temperature reduction (at 180°C) on metal surfaces (e.g., Cu).

-

- Rapid heating/cooling capability

- Heats from RT to 450°C in ≤2s, and gas-accelerated cools, minimizing thermal mismatch deformation, preventing bump shorting, and improving bonding efficiency.

-

- Full-process Inert Atmosphere

- Post-activation transfer and bonding occur entirely in an inert atmosphere to avoid air exposure and oxidation, ensuring higher bonding quality.

Specifications

-

ltemsSpecification

-

Bonding force range1-3000N

-

Bonding force stablility1~50N:±0.5N

51~3000N:±2N -

Wafer size8/12 inch compatible

-

Bonder temperatureRT~450℃

-

Bonder stability±0.5℃

-

Bonder heating rate(RT-450℃)6s@50*50mm; 2s@32*32mm

-

Post-bonding accuracy≤±2μm;≤±1μm;≤±500nm

-

Activation chamber atmosphereHydrogen radical activation, plasma activation.

-

Bond chamber atmosphereInert atmosphere