- iSABers Group Co., Ltd.

iSABers Group Co., Ltd. is a national high-tech enterprise at the forefront of semiconductor bonding and integration technologies in China. The company's core competencies lie in R&D and manufacturing of advanced bonding equipment and high precision bonding process solutions, with applications spanning cutting-edge domains including advanced packaging, semiconductor device fabrication, wafer-level heterogeneous integration, and MEMS sensor production.

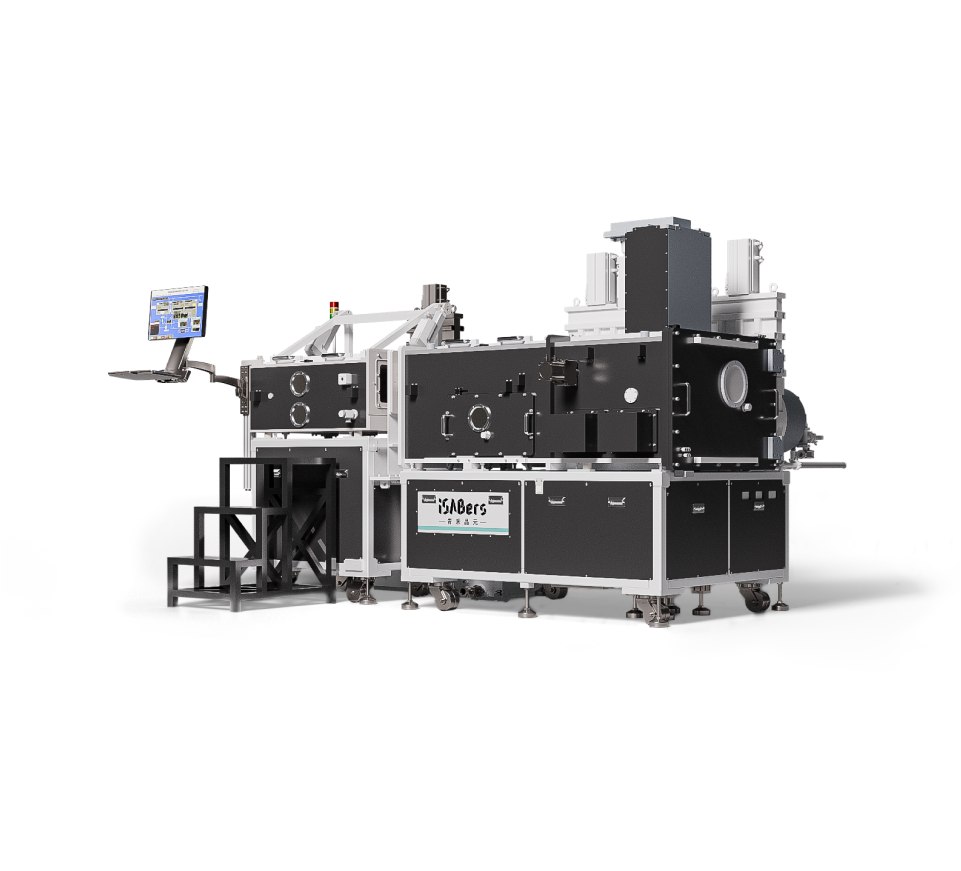

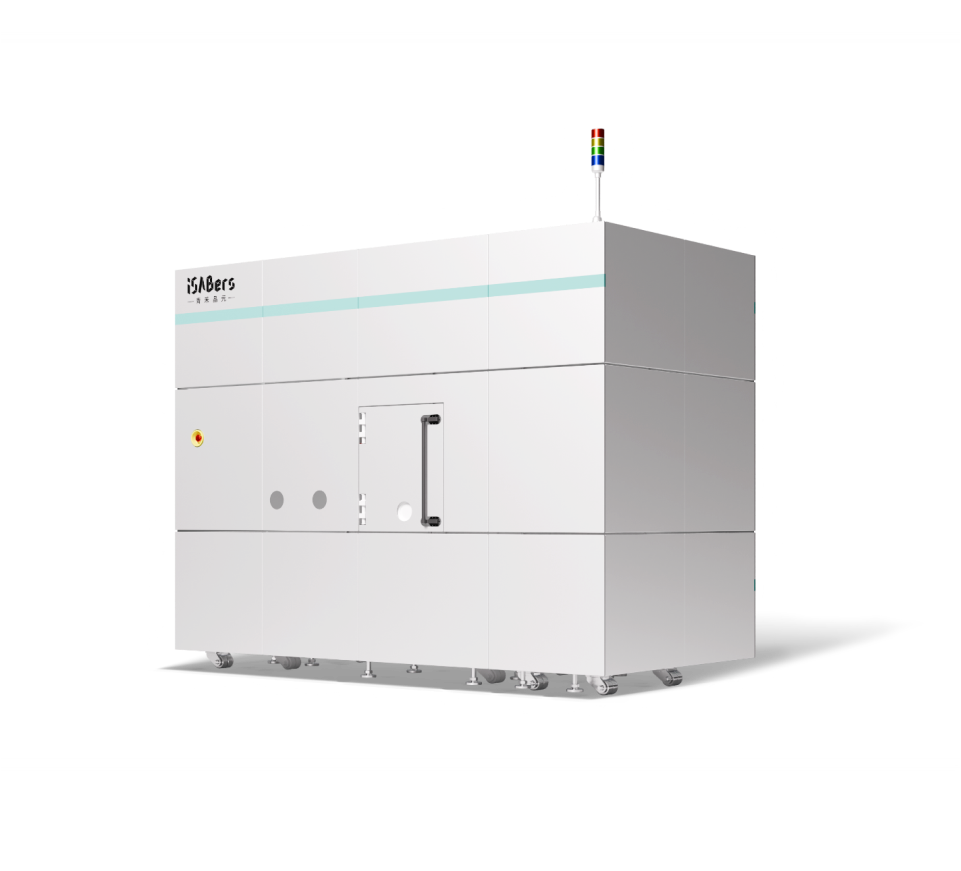

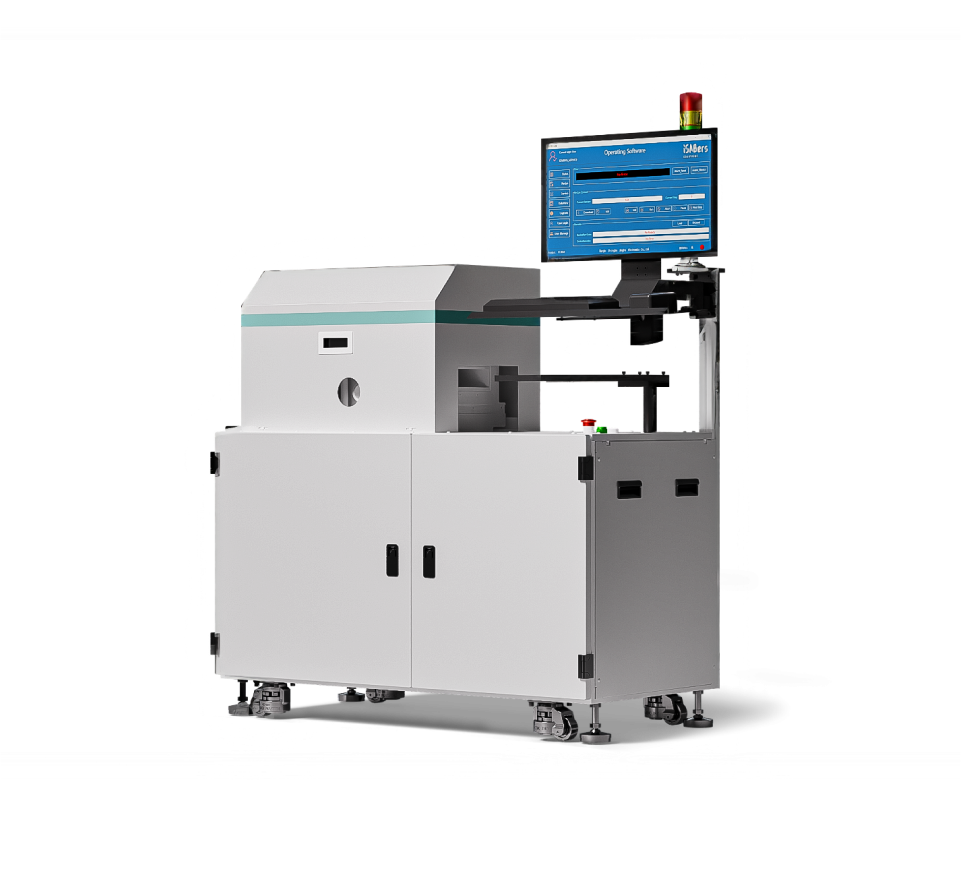

Through its dual-drive strategy of "Equipment Manufacturing + Process Services", the company delivers end-to-end semiconductor bonding solutions. Its proprietary technology portfolio comprises four self-developed product lines with independent IP rights: Ultra-High Vacuum Room-Temperature Bonding Systems, Hybrid Bonding Equipment, Thermocompression Bonding Systems, and Customized Process Service Packages.

Driven by continuous innovation, iSABers is committed to providing high-precision, process-stable, and cost-competitive bonding technologies to the global semiconductor ecosystem, empowering strategic emerging industries such as 5G communications, AI, and new energy vehicles.

As one of the few global enterprises mastering full-stack advanced bonding technologies, iSABers Group remains committed to technological innovation. Our breakthrough solutions address industry challenges and fill domestic gaps, earning the trust of leading industry partners. Looking ahead, we will continuously enhance R&D capabilities and market competitiveness to deliver superior bonding solutions, driving sustainable growth in the semiconductor industry.

-

- 2020

- Founded

-

- 30000+

- Site Area

-

- 5

- R&D & Production Centers

-

- 200+

- Global Patents

-

- Ultra-high Vacuum Technology

- Overcoming challenges in activation and alignment under vacuum environments.

01 -

- Surface Activation Technology

- Mastered full-spectrum surface activation technologies (ICP/CCP/FAB), enabling complete coverage of all wafer bonding applications.

02 -

- Sub-micron Precision Alignment Technology

- Expertise in Face-to-face, Inter-chip Coaxial, and Infrared Transmissive methods.

03 -

- Temperature and Pressure Control Technology

- Ensured high-temperature/high-pressure uniformity

04 -

- Single-wafer Spin Coating/ Cleaning Technology

- High-speed rotational balance and contamination-free processes guarantee exceptional bonding yield.

05