-

Group News2023-05-26

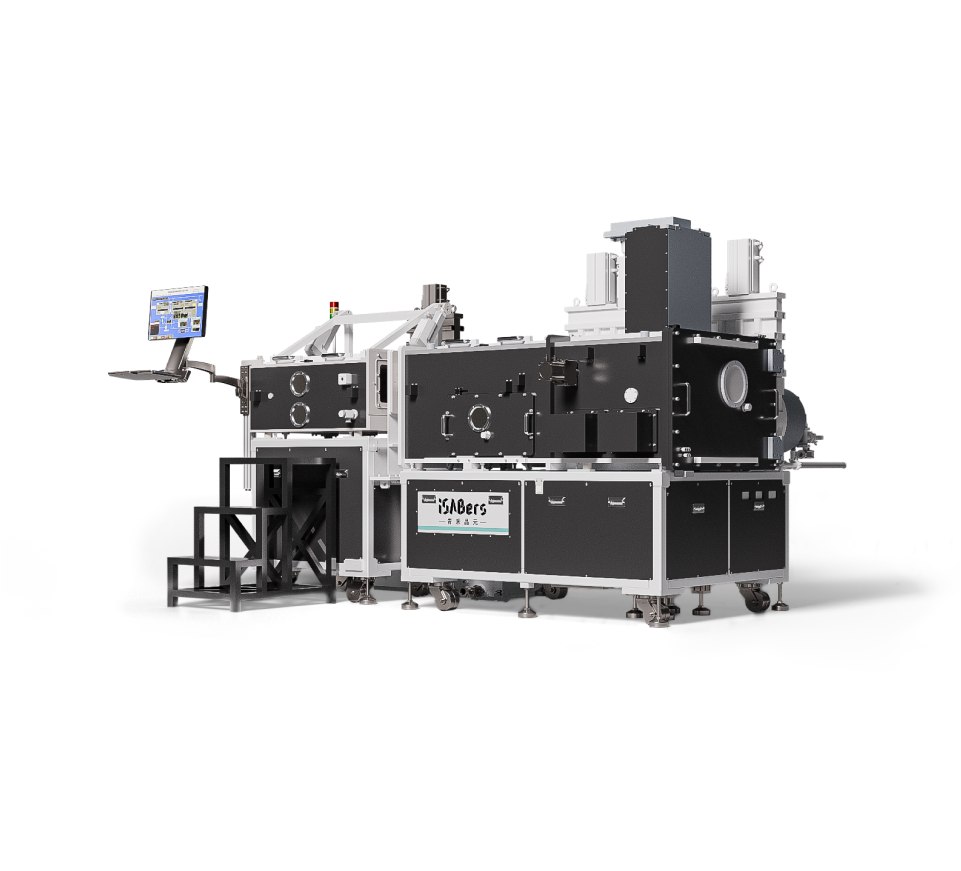

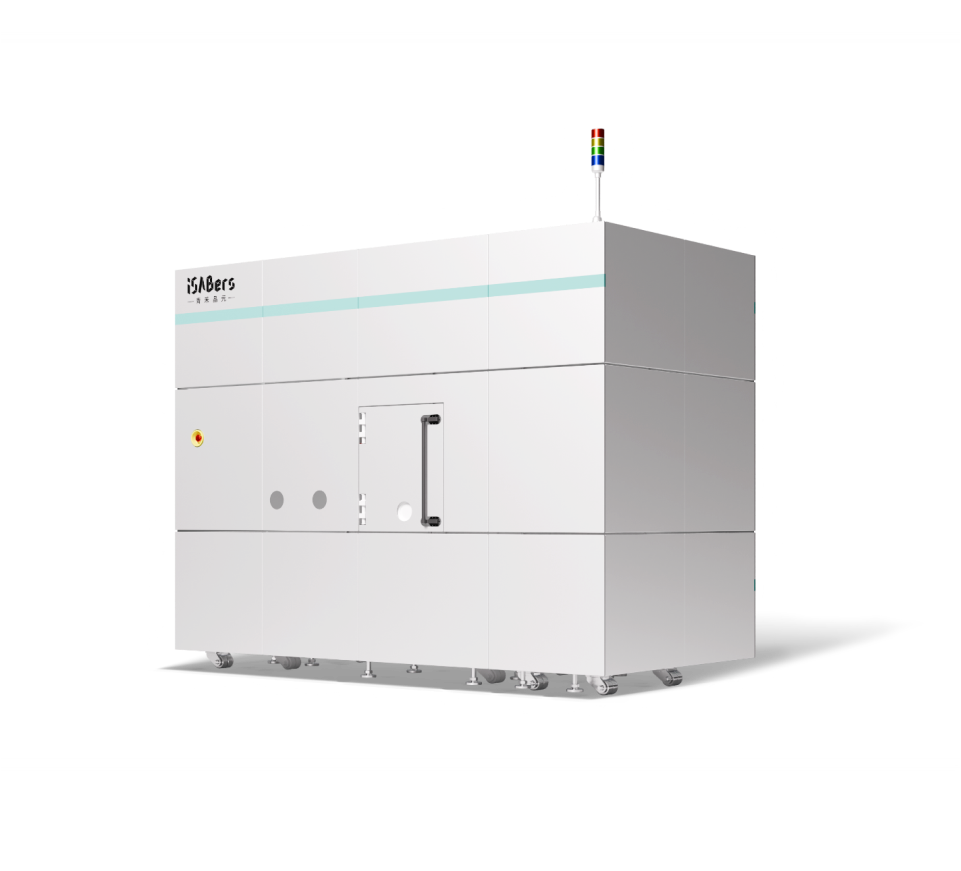

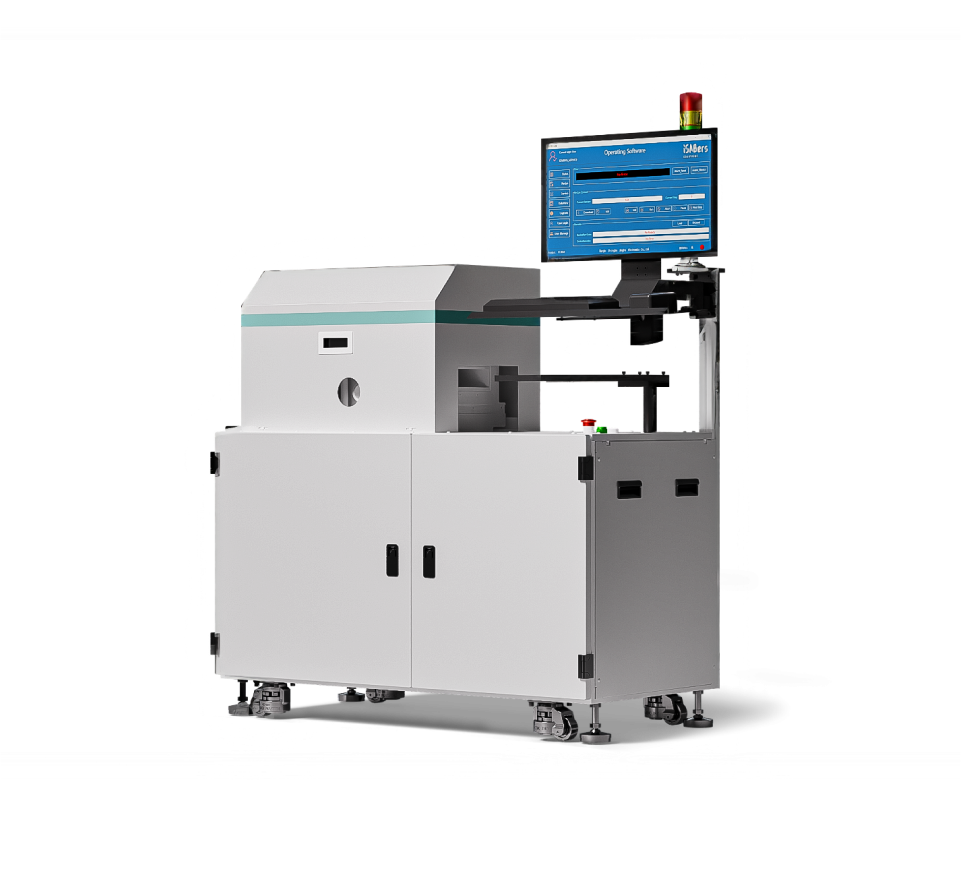

- Domestic First Advanced Semiconductor Composite Substrate Production Line Operational; iSABers Secures Investments from Renowned Institutions

Reporter | Chen Mei

▌Nearly Six Rounds of Financing in Three Years: Resolving Bottlenecks in Advanced Semiconductor Composite Substrate Materials

▌Phase I Capacity: 30,000 Wafers, Future Focus on 8-inch Substrates

Dr. Mu's confidence stems from technological maturity and cost reduction. "Take silicon carbide as an example. The main method to obtain materials domestically is still the 'crystal growth' method. However, this method is highly energy-intensive and requires temperatures as high as 2,000°C to 'grow' the material. More importantly, the 'crystal growth' process has poor stability and low yield, resulting in scarce high-quality silicon carbide materials and high prices."

The core reason for iSABers' rapid production is technological innovation. "The company uses the 'composite' principle to bond high-quality and low-quality substrate materials, fully utilizing both high-quality and low-quality materials. This method effectively reduces material costs and ensures the supply of high-performance, low-cost substrate materials," Dr. Mu explained.

By independently manufacturing each layer of material and final adjustment, iSABers has overcome the challenge of material acquisition. From the perspective of final products, composite substrates can achieve better performance, lower costs, and higher yield rates. Regarding the transition from 6-inch to 8-inch substrates, Dr. Mu is very confident: "If using the 'crystal growth' method, the difficulty of 8-inch is geometric. However, using the 'composite' method, the process from 6-inch to 8-inch is the same, only requiring adjustments to the equipment. Moreover, it does not involve temperature effects, and many processes are completed at room temperature."

▌Post-Mass Production Cost Reduction and Future IPO Plans

Given the explosive growth potential of the industry, Mu Fengwen has harbored ambitions to take the company public since its founding. "Technological innovation is the cornerstone of the composite substrate materials industry. Once technical barriers are overcome, establishing production lines and scaling capacity becomes a natural progression. With robust downstream demand, capacity expansion will accelerate rapidly, and the company's strategic direction is clear," she stated.

Mu plans to meet the SSE STAR Market listing criteria by 2026 and submit IPO applications thereafter. "Our current priority is to rapidly commercialize products and gain broad market acceptance," she emphasized.

Industrial capital investors, including WeHao Capital (Will Semiconductor's affiliated fund), Sungrow, and XinDongNeng, have actively participated in financing rounds, drawn to the company's growth potential and market applications. To date, iSABers' first advanced semiconductor composite substrate production line ranks among the most advanced in China's startup landscape.

-

Latest News

- 2025-05-01

- Pay tribute to the strivers in the semiconductor industry and wish you a happy May Day!

-

Latest News

- 2025-04-21

- iSABers Co-hosted – 2025 China International Seminar on Low-Temperature Bonding and 3D Integration Technology Invites You to Participate

-

Latest News

- 2025-03-28

- iSABers SEMICON Moment: Offline Innovation Sharing Session Successfully Held

-

Latest News

- 2025-03-27

- iSABers' SEMICON Moment: Showcasing China's Solutions for Advanced Bonding Technology

-

Latest News

- 2025-03-21

- SEMICON In-Person Advanced Bonding Technology Breakthroughs Symposium